Automatic Egg Tray Machine Benefits For Pulp Packaging Businesses

A computerized egg tray machine provides a great investment for just about any egg tray manufacturing business. With such a machine, the production line can be created considerably more efficient. A company can go from producing less than 500 pieces per hour by using a manual machine to over 6000 pieces an hour with a fully automatic machine according to the model. Great working efficiency, easy of operation and high automatic are typical benefits that will make fully automatic paper egg tray machine such a great investment. Machines might be customized to meet the criteria of any specific egg tray manufacturing business plans.

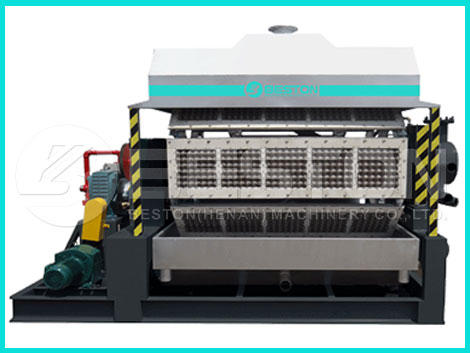

The egg tray manufacturing process has 4 stages: plumping, molding, drying and packing. Every one of those systems may be automated together with the best machines. By having an automatic pulp forming machine, waste paper may be transformed into pulp molded items like egg trays, egg cartons, etc. For example, the BTF-5-12 model from Beston features a production capacity of 5000-6000 pieces each hour and requires a labor force of 5-7. It has a total power of 153 kW and hourly material consumption rates of 459kg of paper and 1377L water. It might are powered by coal, natural gas or diesel. All machines from Beston could be independently adjusted for optimal performance in differing local conditions. Designers in the manufacturer work with your company to create modifications to each system so the machine you order meets your unique operating specifications. Click here to know more: https://bestoncompany.com/.

One of the greatest benefits of fully automatic egg tray making machines over semi-automatic machines besides faster production rates is because they have integrated drying and packing devices. This means that the whole production line might be automated and investors will start egg tray manufacturing businesses in environments that aren't fitted to rapid natural air drying processes, including locations that have cold, humid climates.

The egg tray drying system includes a conveyor belt that automatically transfers wet finished trays on the drying room. Heat blowers than rapidly try the trays before they can be automatically transferred to a counter and packing machine. See the small egg tray machine here.

Automatic egg tray making machines are extremely simple to operate and businesses can take advantage of large profits using their investment. Naturally, when you live in a location by using a hot, dry climate, you may not need to purchase a model having an integrated heated drying system. If that is the case, your investment costs is going to be far lower, helping you to enjoy higher annual profits.

For all those trying to place their egg tray manufacturing business to the next level, there is absolutely no better investment than a top-of-the-range fully automatic machine. This kind of machine can save you lots of money on labor costs and raise the output production rate of your respective business massively.

As well as being able to manufacture egg trays with a fully automatic paper pulping molding machine, you may also produce a range of other packing products by changing the molds. Examples of additional packing products you possibly can make include egg cartons, fruit trays, cup trays, seed pots plus more. Visit the site: https://bestoncompany.com/paper-pulp-moulding-machine/.