Types Of Paper Egg Tray Making Machines

An egg tray making machine will be the primary device employed to help make paper egg trays. These kinds of products assist in the storage and transportation of fragile commodities. The paper pulp egg tray machine works on the principle of recycling waste paper like magazines, books, or carton boxes. There are actually four comprehensive stages: pulping, molding, drying, and packaging, that the machines use before the finishing of production. However, you will find three several types of egg tray making machines. The distinguishing factor emanates from their modes of operation. Additionally, it affects their pricing and amount of production. Here are the three variables.

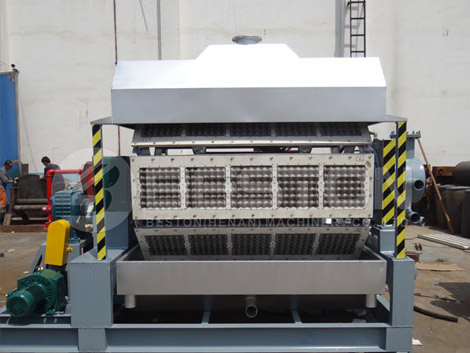

Fully Automatic Egg Tray Machine

The fully automatic egg tray making machine is the ideal under this category. The true reason for its popularity in big companies is its high productivity. Models here can make a array of 4000 to 6000 pieces of trays every hour. Working together with it may expand your company while meeting every demand you may have in spite of the market coverage. The product works efficiently as all its equipment works without making use of manual input. Your third amount of production, the drying stage, is really what results in the big difference. Here, the automatic machine uses the metal or brick drying system, which is quite useful. Nevertheless, the operating is easy, and yes it works in an eco friendly manner. Although your investments will probably be limited, you may take advantage of high returns. Click here to know more: https://bestoncompany.com/.

Semi-Automatic Egg Tray Making Machine

The semi-automatic egg tray making machine works in a basically similar way to the mechanical design. However, the price of production is much lower, therefore may be the rate of production. The model is ideal for companies having an average interest in the appropriate end products. Additionally, the plant uses either the brick of metal drying systems. The development margin falls from 2000 to 5000 pieces each hour. The device is eco-friendly since it does not release any wastes in to the atmosphere. Installation and maintenance also have a shorter duration. Should you invest in this type, you may suit your customers regarding their preferences and quantity. More information on automatic egg tray making machine here.

Manual Egg Tray Making Machine

The manual version of the egg tray making machine will be the cheapest with regards to operations. However, the low costs come at the fee for low productivity. Normally, it might generate 1000 to 3000 pieces each hour. The speed makes it suited to firms that produce over a small scale. However, the requirement for continuous manual input on the various stages also slows the production rate. The crucial step, the drying stage, employs natural drying on a sunny day, which will come with shortcomings. It only works efficiently on days where the forecast predicts sunlight should come out for an extended period. Otherwise, you will need to go backwards and forwards, trying to obtain the required degree of drying. Furthermore, you will need to invest further in employees as, with out them, the device becomes useless. Visit the site: https://bestoncompany.com/egg-carton-making-machine/.

As discussed above, at this point you understand in-depth the different types of egg tray making machines. A broad knowledge of your requirements will help you for making an accurate decision.